1. Preventing Major Heavy‑Equipment Accidents

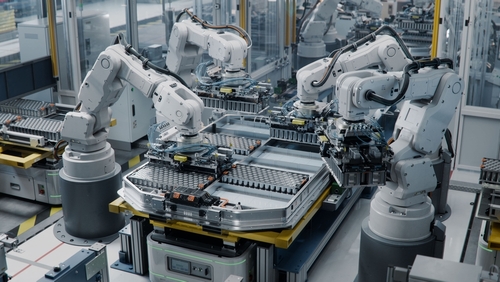

FBOE’s vision sensors integrate with various heavy machinery to deliver robust collision-prevention solutions.

Prioritizing worker safety, we help avert critical industrial accidents.

Monitors driver blind spots caused by loads in real-time to prevent collisions. Removable wireless sensors attach freely to cargo to completely eliminate blind zones.

Detects sudden worker movement and issues real-time alerts to prevent accidents. Helps drivers recognize worker presence within operation zones to minimize collision risk.

Tracks loads’ positions and paths in real time to prevent collisions. Detects potential collisions between lifted objects, structures, and personnel within operation areas.

Accurately detects variable structures like large ship blocks to remove collision risks. Uses LiDAR to measure actual distances and monitor surroundings continuously.

Monitors the real-time status and placement of blocks during assembly to visualize overall ship progress. Tracks start, move, and completion times to clarify assembly stages.

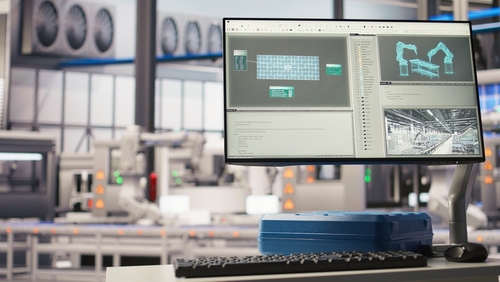

Records statuses across manufacturing steps (machining→coating→inspection) in real time. Helps identify delays or missing steps swiftly.

Tracks workers’ locations and states in the workspace in real time to reduce collision risk. Notifies when workers are within machinery operation zones.

Visualizes completion rates and progress across the entire process, providing clear insight into current status and location. Enables quick identification of bottlenecks or missing steps through end-to-end workflow visibility.

Tracks how parts, blocks, and materials move and distribute within workspace via spatial coordinates. Optimizes material flow by analyzing repetitive routes and redundant crossings.

Accumulates and visualizes routes of heavy equipment like forklifts and transporters. Identifies bottlenecks, high-speed zones, and frequent stoppages to locate risk areas.

Evaluates worker and equipment concentration by time zone to quantify overcrowding or underutilization. Informs redesign of rest, work, and material zones and defines safe-distance criteria.

By learning patterns of repeated close encounters, collision history, and congestion zones, the system predicts areas with high accident potential. This enables proactive risk zone designation and integration with real-time alert systems.